Ruihan's standard ER collet is widely used in the clamping system, to clamp end mills ,drills,taps, reams etc.

Can be used to hold any type of round shank tool

Flexibility to clamp a wide range of tool shanks

High accuracy and concentricity

The ER collet, also known as the "Elastic Retention collet," is a widely used tool in precision machining. It is designed to securely hold cylindrical workpieces, such as drills, milling cutters, reamers, and taps, during machining operations. ER collets are known for their exceptional grip, concentricity, and repeatability, making them indispensable tool in industries like aerospace, automotive, and medical device manufacturing.

An ER collet is a type of collet that uses a compression mechanism to grip and hold tools with cylindrical shanks. Its design consists of a cylindrical body with multiple slits or splits along its length. These splits provide elasticity, allowing the collet to expand and contract to accommodate different tool sizes. The ER collet is then secured within a collet chuck, providing a firm grip on the tool.

The ER collet is made of spring steel 65Mn, which is the best steel material to guarantee its hardness HRC44~48.

All data conforms to standard DIN6499B and has two runout levels,0.01mm and 0.015mm.

Ruihan has the most comprehensive ER collet choices, from the smallest ER8 collet to the biggest ER50 collet.

①Superior Gripping Power: ER collets offer excellent gripping power, ensuring a secure hold on the tool. This feature prevents tool slippage during high-speed machining operations, reducing the risk of accidents and improving overall productivity.

②Wide Range of Sizes: ER collets are available in various sizes, accommodating a wide range of tool diameters. From ER8 to ER50, each collet size can accommodate a specific tool diameter, providing flexibility in tool selection.

③Excellent Concentricity: ER collets exhibit exceptional concentricity, allowing for precise machining. This high level of concentricity minimizes runout, resulting in accurate and consistent machined parts.

④Quick Tool Changes: ER collets enable rapid tool changes, saving valuable machining time. With a simple tool insertion and tightening of the collet chuck, operators can switch between tools efficiently.

⑤Versatility: ER collets are compatible with various types of cutting tools, including drills, end mills, reamers, and taps. This versatility makes them suitable for a wide range of machining applications.

ER collets come in different types, each designed for specific applications. The most commonly used types are ER16, ER20, ER25, ER32, and ER40. These types correspond to different maximum tool diameters, providing options for various machining needs.

| ER Collet Type | Maximum Tool Diameter (mm) |

| ER16 | 10 |

| ER20 | 13 |

| ER25 | 16 |

| ER32 | 20 |

| ER40 | 26 |

ER8 collet 1-5mm 0.5mm step

ER11 collet 1-7mm 0.5mm step

ER16 collet 1-10mm 1mm step

ER20 collet 1-13mm 1mm step

ER25 collet 2-16mm 1mm step

ER32 collet 3-20mm 1mm step

ER40 collet 3-26mm 1mm step

ER50 collet 6-34mm 1mm step

The inch sizes are also available.

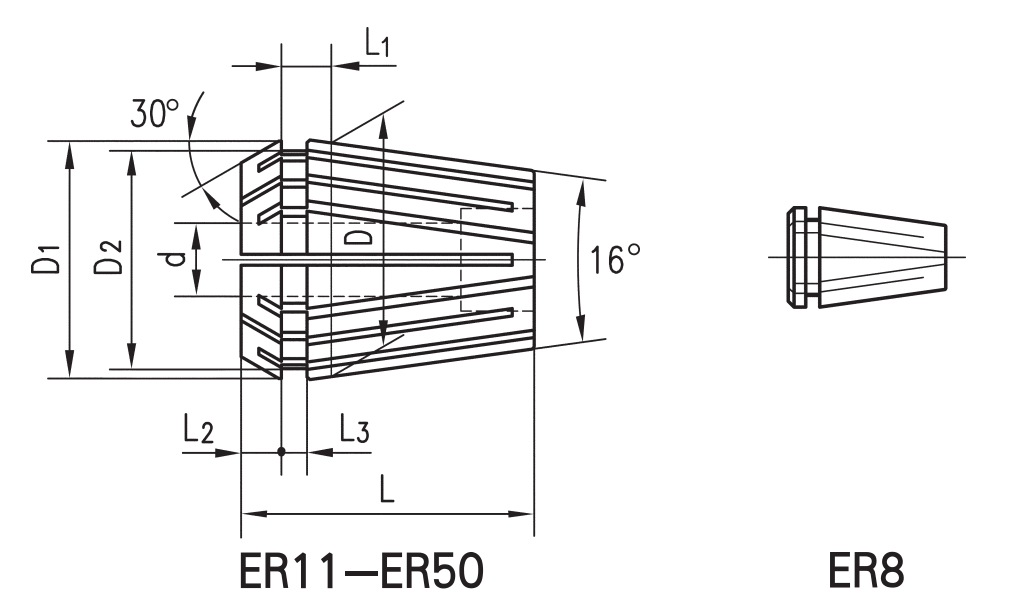

| Model | dH7 | D | D1 | D2 | L | L₁ | L₂ | L3 | Collapsible capacity |

| ER8 | ≥1.0~5.0 | 8 | 8.45 | 6.5 | 13.5 | 2.98 | 1.5 | 1.2 | 0.5 |

| ER11 | ≥1.0~7.0 | 11 | 11.5 | 9.5 | 18.0 | 3.8 | 2.5 | 2.0 | 0.5 |

| ER16 | ≥1.0~2.5 | 16 | 17 | 13.8 | 27.5 | 6.26 | 4.0 | 2.7 | 0.5 |

| >2.5~10.0 | 16 | 17 | 13.8 | 27.5 | 6.26 | 4.0 | 2.7 | 1.0 | |

| ER20 | ≥1.0~2.5 | 20 | 21 | 17.4 | 31.5 | 6.36 | 4.8 | 2.8 | 0.5 |

| >2.5~13.0 | 20 | 21 | 17.4 | 31.5 | 6.36 | 4.8 | 2.8 | 1.0 | |

| ER25 | ≥1.0~2.5 | 25 | 26 | 22.0 | 34.0 | 6.66 | 5.0 | 3.1 | 0.5 |

| >2.5~16.0 | 25 | 26 | 22.0 | 34.0 | 6.66 | 5.0 | 3.1 | 1.0 | |

| ER32 | ≥2.0~2.5 | 32 | 33 | 29.2 | 40.0 | 7.16 | 5.5 | 3.6 | 0.5 |

| >2.5~20.0 | 32 | 33 | 29.2 | 40.0 | 7.16 | 5.5 | 3.6 | 1.0 | |

| ER40 | ≥3.0~26.0 | 40 | 41 | 36.2 | 46.0 | 7.66 | 7.0 | 4.1 | 1.0 |

| ER50 | ≥6.0~10.0 | 50 | 52 | 46.0 | 60.0 | 12.6 | 8.5 | 5.5 | 1.0 |

| ≥10,0~34,0 | 50 | 52 | 46,0 | 60,0 | 12.6 | 8.5 | 5.5 | 2.0 |

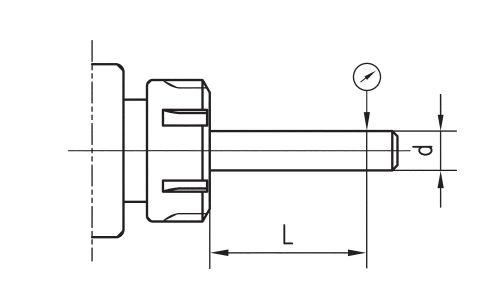

| D | L | Run out tolerance | ||||

| A | B | C | 1 | Ⅱ | ||

| 1.0~1.6 | 6 | 0.005 | 0.008 | 0.010 | 0.010 | 0.015 |

| >1.6~3.0 | 10 | |||||

| >3.0~6.0 | 16 | |||||

| >6.0~10.0 | 25 | |||||

| >10.0~18.0 | 40 | 0.015 | 0.020 | |||

| >18.0~26.0 | 50 | |||||

| >26.0~30.0 | 60 | |||||

| >30.0~34.0 | 80 | 0.020 | 0.030 | |||

ER collets find widespread applications in the machining industry. Some common uses include:

CNC Milling: ER collets are extensively used in CNC milling machines to secure end mills, drill bits, and other cutting tools. The superior grip and concentricity of ER collets ensure precise milling operations.

Turning and Lathing: ER collets are also employed in turning and lathing operations. They securely hold turning tools, allowing for accurate and repeatable cuts.

Reaming and Boring: ER collets provide a reliable grip on reamers and boring tools, ensuring precise hole sizing and surface finish.

Thread Cutting: ER collets are ideal for holding taps during thread-cutting operations. Their gripping power and concentricity contribute to clean and accurate threads.

Engraving and Deburring: ER collets can hold engraving tools and deburring blades, facilitating intricate and precise surface finishes.

ER collets are commonly made of high-quality spring steel or carbide, offering durability and strength.

To select the appropriate ER collet size, match the maximum tool diameter with the corresponding ER collet type. For example, a tool with a 10mm diameter requires an ER16 collet.

ER collets are primarily designed for cylindrical tools. However, certain ER collet types, such as ER16 and ER20, offer limited compatibility with tools that have slight non-cylindrical shapes.

ER collets are generally suitable for light to medium-duty machining. For heavy-duty applications, hydraulic or shrink-fit tool holders are recommended.

To maintain ER collets, regular cleaning and lubrication are essential. Clean the collets using a non-corrosive solvent, remove any debris, and apply a light coating of lubricant.

Yes, ER collets can be used in manual machining operations as well. The same principles of tool selection, collet insertion, and tightening apply to manual machining processes.

ER collets are an invaluable tool in precision machining, offering exceptional gripping power, concentricity, and versatility. Whether you are a machinist, engineer, or hobbyist, the ER collet is a must-have for achieving accurate and reliable machining results. Understanding the various types, sizes, and applications of ER collets empowers you to make informed decisions when selecting the right tool for your machining needs.