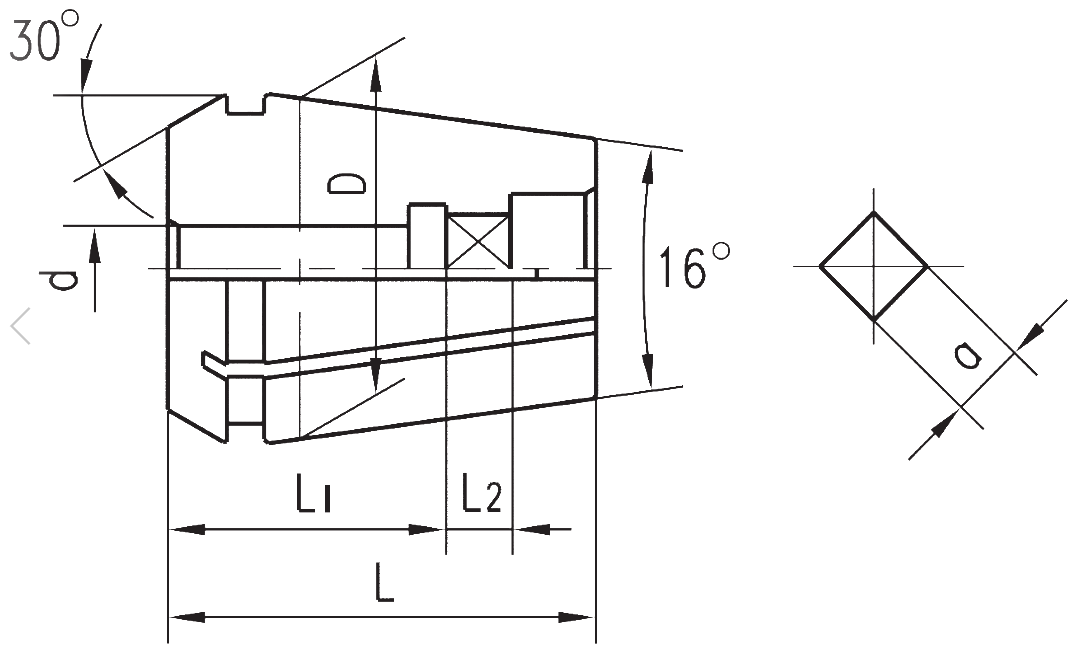

Also known as ER Tapping Collet

The collet bore is the exact tool diameter, with a square drive

Special design locks flat-sided tap shanks into the collet

Provides maximum concentricity, with the positive driving force

Reduces tapping clearance requirements

An ER Tap Collet is a type of collet used in tapping operations, where a tap is used to cut threads into a hole. It is similar to other ER collets in that it is designed to hold tools securely in place in a milling machine, drill press or other machining equipment, but it is specifically designed for use with taps.

ER Tap Collets are available in various sizes to match the different tap shank diameters used in tapping operations. ER Rigid Tapping Collets with Square Drive for synchronous tapping operations using any ER collet chuck. The collet bore is the exact tool diameter, with a square drive, for accuracy and rigidity. Available sealed for coolant-through applications, as well as in DIN and JIS standard metric sizes.

| Model No. | ER16G-d | ER20G-d | ER25G-d | ER32G-d | ER40G-d |

| D | 16 | 20 | 25 | 32 | 40 |

| L | 27.5 | 31.5 | 34 | 40 | 46 |

| d | 3.5∼8 | 3.5∼10 | 3.5∼16 | 3.5∼20 | 3.5∼25 |

| dx a | 3.5×2..7 | 4.0×3.0 | 4.5×3.4 | 5.5×4.3 | 6.0×4.9 | 7.0×5.5 |

| 8.0×6.2 | 9.0×7.0 | 10×8.0 | 11×9.0 | 12×9.0 | 14×11 | |

| 16×12 | 18×14.5 | 20×16 | 22×18 | 25×20 |

One of the advantages of using an ER Tap Collet is that it provides a high level of accuracy and repeatability when cutting threads. The collet's grip on the tap shank ensures that the tap is held firmly in place, reducing the risk of chatter, deflection or breakage. This can result in higher-quality threads and a more efficient tapping process overall.

Another advantage of ER Tap Collets is that they can be quickly and easily changed out to accommodate different tap sizes. This allows operators to adapt to different threading requirements without the need for extensive tool changes or adjustments.

Overall, ER Tap Collets are a useful tool for those involved in tapping operations, offering increased accuracy, reliability and versatility compared to traditional tapping methods. Get a quick quote.

A: An ER Tap Collet is a specialized tool holder used in CNC machines and milling machines to securely hold and position taps for precise threading operations. It is designed to provide stability and accuracy during tapping processes.

A: EER Tap Collets offer several benefits, including high precision, excellent clamping force, and reduced vibration. These features ensure accurate and consistent threading, extending the lifespan of taps and improving the overall quality of the machined parts.

A: To select the appropriate ER Tap Collet, consider factors such as the tap size, the type of material being threaded, and the specific requirements of your machining process. Refer to the manufacturer's specifications to ensure compatibility with your machine and tap.

A: To install an ER Tapping Collet, insert the collet into the collet chuck and make sure it is properly seated. Then, insert the tap into the collet, ensuring it is securely clamped. Tighten the collet nut to the specified torque to achieve optimal clamping force.

A: Yes, ER Tap Collets are versatile and can be used with various types of taps, including spiral point taps, spiral flute taps, and straight flute taps. Ensure the collet size matches the tap shank size for a secure fit.

A: Regular maintenance includes cleaning the collets and chuck to remove debris and ensuring they are free from damage or wear. Lubricate moving parts as needed and store collets in a clean, dry environment to prevent corrosion.

A: If the collet is not holding the tap securely, check for debris or damage on the collet, tap, or chuck. Ensure the collet is properly seated and that the collet nut is tightened to the recommended torque. If the problem persists, consider replacing the collet.

A: Yes, ER Tap Collets are designed to withstand high-speed tapping operations. However, ensure that the collet and tap are properly balanced and that the machine's speed and feed rates are set according to the manufacturer's recommendations.

A: ER Tapping Collets are compatible with a wide range of CNC machines and milling machines. However, always verify the compatibility of the collet system with your specific machine model and its tooling requirements.

A: ER Tap Collets come in various sizes to accommodate different tap shank diameters. Common sizes include ER11, ER16, ER20, ER25, ER32, and ER40. Check the product catalog for the full range of available sizes and specifications.

For more information or assistance in selecting the right ER Tap Collet for your needs, please contact our customer support team.