HRC: 55

Grain Size: 0.4UM

Coating: AlTiN

Helix Angle: 35

Flutes: 4&3

Application: Tool steel, quenched and tempered steel, Carbon steel, cast iron(4 Flutes); Professionfor Copper & Aluminum(3 Flutes).

Non-standard production & OEM are welcome anytime.

Roughing End Mills, also known as ripping cutters or hoggers, are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Coarse tooth roughing end mills remove large chips for heavy cuts, deep slotting and rapid stock removal on low to medium carbon steel and alloy steel before a finishing application. Fine tooth roughing end mills remove less material but the pressure is distributed over many more teeth, for longer tool life and a smoother finish on high-temperature alloys and stainless steel.

Carbide Roughing End Mills

The primary purpose of the roughing end mill is to quickly remove large amounts of material and roughly shape the workpiece into the required form. This is done so that future processing may be carried out in a way that is both more convenient and effective. When doing rough machining, the goal is to swiftly remove the blank allowance. A high feed rate and a deep cutting depth are often chosen for this process so that as many chips as possible may be removed in a short amount of time. Therefore, roughly machined items often have low precision, a rough surface, and a rapid production rate. The semi-finishing and finishing processes frequently require preparation from the roughing step.

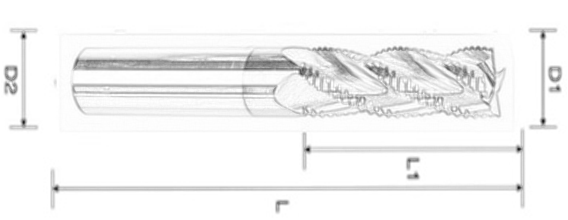

| Type | d | D | L1 | L | Flute |

| HRC55-RS4-4*50 | 4 | 4 | 10 | 50 | 4 |

| HRC55-RS4-5*50 | 5 | 6 | 13 | 50 | 4 |

| HRC55-RS4-6*50 | 6 | 6 | 15 | 50 | 4 |

| HRC55-RS4-8*60 | 8 | 8 | 20 | 60 | 4 |

| HRC55-RS4-10*75 | 10 | 10 | 25 | 75 | 4 |

| HRC55-RS4-12*75 | 12 | 12 | 30 | 75 | 4 |

| HRC55-RS4-16*100 | 16 | 16 | 45 | 100 | 4 |

| HRC55-RS4-20*100 | 20 | 20 | 45 | 100 | 4 |

| Type | d | D | L1 | L | Flute |

| HRC55-RAL3-4*50 | 4 | 4 | 10 | 50 | 3 |

| HRC55-RAL3-5*50 | 5 | 6 | 13 | 50 | 3 |

| HRC55-RAL3-6*50 | 6 | 6 | 15 | 50 | 3 |

| HRC55-RAL3-8*60 | 8 | 8 | 20 | 60 | 3 |

| HRC55-RAL3-10*75 | 10 | 10 | 25 | 75 | 3 |

| HRC55-RAL3-12*75 | 12 | 12 | 30 | 75 | 3 |

| HRC55-RAL3-16*100 | 16 | 16 | 45 | 100 | 3 |

| HRC55-RAL3-20*100 | 20 | 20 | 45 | 100 | 3 |

Roughing End Mills can achieve quick feed, and subsequent finishing operations may remedy any errors that may have been made, which helps to assure product quality.

When the processing phases are divided, the benefits of using rough and final end mill equipment may be exploited to their maximum potential. Roughing End Mills are characterized by having high power, high efficiency, and strong stiffness, whereas finishing equipment is characterized by having high precision and minimal error.

Roughing end mills can discover a variety of flaws in the blanks, such as sand holes, air holes, inadequate machining allowance, etc., which makes it convenient for quick repair or scrapping, so that processing time and expense are not wasted.

The workpiece has a significant amount of residual stress after it has been subjected to hot working. Aging the workpiece may be arranged to remove the residual stress, and final machining can be set to remove the deformation that has occurred after the workpiece has cooled.

Before the mechanical finishing, the roughing end mill is used to prepare the surface. Finishing can preserve the surface from wear caused by the subsequent steps.

Despite everything that has been mentioned, no tooling component can stay forever. Even those who take the utmost care possible in maintaining their roughing end mill may eventually run into a situation in which some of their end mills are no longer sharp enough to be useful in metalworking.

Your initial reaction may be to go out and purchase a completely new roughing end mill to use as a substitute. However, as carbide tooling may be rather pricey, opting for that default position can end up being quite costly. Roughing end mills are a solution that can save money while maintaining the original operating capability for individuals who are willing to consider other options.

The roughing end mill may save you anywhere from fifty to ninety percent of the price of a brand-new tool, making it one of the most cost-effective ways to reduce your expenses. Roughing end mills may often be used three to five times on most instruments. Such significant reductions in per-unit costs occur without an equivalent loss in quality, which, as a logical consequence, results in a better profit margin for the entirety of a particular CNC machining process.

Keep in mind, however, that before the cutting edge of a roughing end mill becoming completely worn and useless, the end mill must be sharpened. If you don’t do this, probably, you won’t be able to fully recover its performance capability, and the expenses of resharpening can end up being more than the advantages. As a result, it is beneficial to develop a resharpening schedule for a roughing end mill well in advance of the time when its life is expected to come to an end. This allows the tool to be sent for regrinding at the optimal time, thereby reducing the amount of downtime experienced and the likelihood of the tool failing.

1. Mold processing

Die and mold manufacturing is a specialist field that needs both common and specialized equipment, notably milling cutters, to allow the manufacture of small batches for particular uses. As opposed to conventional mould steels like P-20 and H1355-60HRC Carbide End Mill, clients are increasingly specifying metal for work at mold shops. Aluminum alloys have various benefits for molding, including great machinability, high strength-to-weight ratio, and superior thermal conductivity. Metal removal rates from carbide end mills with the proper cutting geometry and coatings can be four to five times greater than those from moulded steel. Mold finishing time is greatly decreased by readily achieving surface finishes of 16 or higher.

2. Heat-Resistant Alloy Machining

Traditionally, the highest grade tungsten carbide has been used to create end mills. They have sharp teeth as a result of their design, which enables them to polish with extreme accuracy while yet retaining a high level of brightness. The end mills may be counted on to carry out their intended function even under challenging circumstances. One of the numerous uses for this tool, which also serves a variety of other objectives, is the machining of heat-resistant alloys like titanium, stainless steel, and other materials. Some end mills can be used in processes that are carried out at high temperatures because they have a surface that is much more abrasive. Some end mills have a substantially greater range of sizes and shapes than typical end mills and a significantly higher level of abrasiveness.

3. 3C Processing

Aluminum and plastics are the two materials most frequently utilized in the 3C sector. Glass, ceramics, and stainless steel have now been included. End mill providers have significant demands as a result of the intense competitiveness in the 3C industry, which necessitates both quick delivery and exceptionally long tool lives. The 3C electronic, parts machining, and precision mould machining industries mostly employ the long neck and micro end mills. The mobile phone, digital, and other electronic goods in the 3C sector are specifically designed for the micro end mill and long neck end mills. They realize the most professional and highest quality processing requirements and have superior production accuracy. These end mills are more durable and produce products with extremely high finishes. comprehensive tool selection in one location.

4. Aviation Industry

In the aviation sector, milling is widespread. For the components of aircraft wings and engines, complex end mills are employed. In the aviation sector, end mills are now one of the most crucial machining techniques, particularly when working with aluminum alloys.

Aerospace components not only make extensive use of innovative structures, technologies, and materials, but also their intricate design and lack of stiffness need the extensive use of high performance standard end mills and specialized carbide end mills to process components like engines. The carbide end mill system can readily interfere with components and holders while cutting elevated portions. As a result, it’s essential to optimize the route of the carbide milling tool, employing techniques like spiral interpolation for milling and inserting and milling rather than side milling or straight milling. A powerful machining center must be used to manufacture the turbine cartridge in terms of tooling. The analysis of the processing procedure shows that the chassis requires roughing, semi-finishing, and finishing. In the production of such aerospace components, high performance carbide end mills can be used for roughing, standard high performance carbide end mills, and non-standard high performance unique carbide end mills for semi-finishing and finishing.

5. Metal Manufacturing

Carbide end mills come in a broad range of lengths, diameters, flute counts, and other characteristics. They are selected based on the material they are cutting and the level of surface quality needed for the job. A highly sharp cutting edge and a tiny radius are only two of the properties that make carbide end mills excellent for use in metalworking operations including turning, milling, drilling, and tapping. For many metal production applications, carbide end mills provide a reliable and long-lasting option. In comparison to other end mill materials, it has various benefits including a long usable life, the capacity to cut at extremely high speeds, and a superior final surface.

A type of industrial equipment called a carbide end mill is used to cut and shape metals and other solid materials. Cast iron, non-ferrous metals, alloys, and polymers are among of the toughest materials, and carbide end mills are employed for high-speed operations on these materials because of their exceptional heat resistance. A345 solid carbide end mills are used to machine non-ferrous metals like aluminum, brass, and copper, whereas 45–50 HRC carbide end mills

After the roughing operation, the finishing operation is carried out in order to get the desired final geometry and other features. The roughing operation is used to develop a part geometry that is as near as possible to the shape of the finished product in a short amount of time. What exactly is the difference between roughing something out and finalizing it?

Purpose.Finishing is used to improve the surface quality, tolerance, and decrease or minimize the faults that were introduced during roughing. Roughing is mostly used to remove a substantial quantity of superfluous material from the component.

Parameter. During the roughing process, both the feed rate and the cut depth are increased.

Material Removal. Rate The rate of material removal during the roughing phase is greater than during the finishing process.

The surface’s overall finish.The surface quality that is achieved after finishing is superior to that which was achieved after roughing.

Absolute precision Finishing, also known as fine machining, may offer great dimensional precision and narrow tolerance, in contrast to roughing, which cannot.

Instruments for cutting. The inserts and cutting angles must be adjusted to meet the specific requirements of each level of roughness. Since of its ability to absorb cutting pressures, negative rake inserts are well suited for rough machining because this type of machining permits greater cutting rates. When doing finish machining, the use of positive rake inserts is often recommended for achieving the best possible surface finish.

Cutting and modifying metal and other working materials may be accomplished in a one-of-a-kind fashion through the use of roughing end mills and the milling process in general. And because there are so many different types of these cutting tools to pick from, you can find one that is suitable for practically any material or task that you bring to it. If you are interested in learning more about the Roughing End Mill, Ruihan has a variety of options for you to choose from. To cater to your milling requirements, we provide a broad selection of cuts, styles, and dimensions to choose from.