Coating: AlTiN+nAco

Grain Size: 0.3UM

HRC: 60

Helix Angle: 35

Flutes: 2

Application: Profession for Titanium Alloy

Developed by RUIHAN, a renowned name in precision cutting tools, these high-performance end mills offer exceptional quality, durability, and precision for machining titanium alloys. Non-standard production & OEM are welcome anytime.

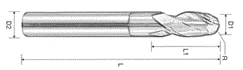

Carbide Ball Nose End Mills For Titanium Alloy

| Type | d | D | L1 | L | Flute |

| HRC60-TT2-R0.5*50 | 1 | 4 | 2 | 50 | 2 |

| HRC60-TT2-R0.75*50 | 1.5 | 4 | 3 | 50 | 2 |

| HRC60-TT2-R1*50 | 2 | 4 | 4 | 50 | 2 |

| HRC60-TT2-R1.25*50 | 2.5 | 4 | 5 | 50 | 2 |

| HRC60-TT2-R1.5*50*D3 | 3 | 3 | 6 | 50 | 2 |

| HRC60-TT2-R1.5*50 | 3 | 4 | 6 | 50 | 2 |

| HRC60-TT2-R1.75*50 | 3.5 | 4 | 7 | 50 | 2 |

| HRC60-TT2-R2*50 | 4 | 4 | 8 | 50 | 2 |

| HRC60-TT2-R2.5*50*D5 | 5 | 5 | 10 | 50 | 2 |

| HRC60-TT2-R2.5*50*D6 | 5 | 6 | 10 | 50 | 2 |

| HRC60-TT2-R3*50 | 6 | 6 | 12 | 50 | 2 |

| HRC60-TT2-R4*60 | 8 | 8 | 16 | 60 | 2 |

| HRC60-TT2-R5*75 | 10 | 10 | 20 | 75 | 2 |

| HRC60-TT2-R6*75 | 12 | 12 | 24 | 75 | 2 |

| HRC60-TT2-R7*100 | 14 | 14 | 28 | 100 | 2 |

| HRC60-TT2-R8*100 | 16 | 16 | 32 | 100 | 2 |

| HRC60-TT2-R9*100 | 18 | 18 | 36 | 100 | 2 |

| HRC60-TT2-R10*100 | 20 | 20 | 40 | 100 | 2 |

| Type | d | D | L1 | L | Flute |

| HRC60-TT2-R2*75 | 4 | 4 | 8 | 75 | 2 |

| HRC60-TT2-R2*100 | 4 | 4 | 8 | 100 | 2 |

| HRC60-TT2-R3*75 | 6 | 6 | 12 | 75 | 2 |

| HRC60-TT2-R3*100 | 6 | 6 | 12 | 100 | 2 |

| HRC60-TT2-R3*150 | 6 | 6 | 12 | 150 | 2 |

| HRC60-TT2-R4*75 | 8 | 8 | 16 | 75 | 2 |

| HRC60-TT2-R4*100 | 8 | 8 | 16 | 100 | 2 |

| HRC60-TT2-R4*150 | 8 | 8 | 16 | 150 | 2 |

| HRC60-TT2-R5*100 | 10 | 10 | 20 | 100 | 2 |

| HRC60-TT2-R5*150 | 10 | 10 | 20 | 150 | 2 |

| HRC60-TT2-R6*100 | 12 | 12 | 24 | 100 | 2 |

| HRC60-TT2-R6*150 | 12 | 12 | 24 | 150 | 2 |

| HRC60-TT2-R7*150 | 14 | 14 | 28 | 150 | 2 |

| HRC60-TT2-R8*150 | 16 | 16 | 32 | 150 | 2 |

| HRC60-TT2-R10*150 | 20 | 20 | 40 | 150 | 2 |

Achieve exceptional cutting efficiency and precision in titanium alloy machining with our Carbide Ball Nose End Mills. Crafted from premium-grade carbide, these tools offer durability, heat resistance, and extended tool life. Shop now for superior milling solutions.

- Premium-grade carbide construction for exceptional strength and heat resistance

- Precise ball nose design for smooth contouring and profiling

- Advanced flute geometry for efficient chip evacuation and reduced heat buildup

- Specialized coating for enhanced wear resistance and extended tool life

- Sharp cutting edge and rigid tool body for minimal vibration and chatter

- Suitable for aerospace, automotive, and medical industries

- Reliable performance for roughing, finishing, and contouring applications

◆Exceptional Machining Performance: The Carbide Ball Nose End Mills from RUIHAN offer exceptional cutting performance, enabling higher machining speeds and feeds. This results in improved productivity, reduced cycle times, and increased efficiency in titanium alloy machining.

◆Precision Machining: The precise ball nose design allows for accurate and intricate machining of complex titanium alloy profiles, contours, and cavities. It ensures excellent dimensional accuracy and superior surface finishes, meeting the high standards required in industries such as aerospace and medical.

◆Extended Tool Life: The superior hardness and wear resistance of our carbide materials, combined with the advanced coatings, contribute to longer tool life. This minimizes the need for frequent tool changes, reducing downtime and overall machining costs.

◆Wide Application Range: Our Carbide Ball Nose End Mills are suitable for machining a variety of titanium alloys, including Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, and Ti-6Al-2Nb-1Ta-0.8Mo, among others. They are ideal for applications in aerospace components, medical implants, and high-performance automotive parts.

Our Carbide Ball Nose End Mills for Titanium Alloy is specifically designed for the following applications:

◆Titanium alloy contouring, profiling, and finishing

◆Titanium alloy cavity machining

◆Titanium alloy pocketing and slotting

◆Titanium alloy mold and die machining

◆Titanium alloy component manufacturing

Our Carbide Ball Nose End Mills for Titanium Alloy is available in a wide range of sizes, flute counts, and shank options to suit specific customer requirements. For detailed product information and availability, please refer to our catalog or contact our sales team.

★Use a high-speed spindle: Titanium alloys are known for their low thermal conductivity, which means they can quickly transfer heat to the cutting tool, causing premature wear or breakage. A high-speed spindle can help dissipate heat and reduce wear on the tool.

★Use a coolant: Applying a coolant during machining can improve tool life by reducing friction and heat buildup. However, be careful not to use too much coolant as it can cause workpiece material to warp or distort.

★Choose the right cutting parameters: The optimal cutting parameters will depend on the specific titanium alloy being machined, such as its hardness, composition, and grain structure. Generally, slower speeds and higher feed rates are recommended for titanium alloys.

★Select the right geometry: Carbide ball nose end mills come in various geometries, including standard, long, and tapered. Choose a geometry that is appropriate for the task at hand, such as roughing or finishing.

★Check for wear regularly: Inspect the end mill regularly for signs of wear or damage, such as chipping or dulling. Replace the tool if it becomes worn to prevent further damage to the workpiece or machine.

Invest in our Carbide Ball Nose End Mills for Titanium Alloy and experience the superior cutting efficiency, precision, and extended tool life they offer. Maximize productivity and achieve outstanding results in your titanium alloy machining projects. Shop now and elevate your milling capabilities. Trust RUIHAN's expertise to enhance your titanium machining capabilities and achieve superior results.