HRC: 60

Coating: AlTiN+nAco

Grain Size: 0.3UM

Helix Angle: 35

Flutes: 4

Application: Profession for Titanium Alloy

Non-standard production & OEM is welcome anytime.

Introducing our high-performance Carbide Square End Mills specially engineered for Titanium Alloy machining. Designed to tackle the challenges of this demanding material, our end mills deliver exceptional precision, durability, and efficiency, ensuring optimal results in your machining projects.

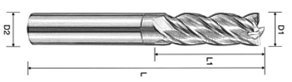

Carbide Square End Mills For Titanium Alloy

| Type | d | D | L1 | L | Flute |

| HRC60-TT4-1*50 | 1 | 4 | 3 | 50 | 4 |

| HRC60-TT4-1.5*50 | 1.5 | 4 | 4 | 50 | 4 |

| HRC60-TT4-2*50 | 2 | 4 | 5 | 50 | 4 |

| HRC60-TT4-2.5*50 | 2.5 | 4 | 6 | 50 | 4 |

| HRC60-TT4-3*50*D3 | 3 | 3 | 8 | 50 | 4 |

| HRC60-TT4-3*50 | 3 | 4 | 8 | 50 | 4 |

| HRC60-TT4-3.5*50 | 3.5 | 4 | 9 | 50 | 4 |

| HRC60-TT4-4*50 | 4 | 4 | 10 | 50 | 4 |

| HRC60-TT4-5*50 | 5 | 5 | 13 | 50 | 4 |

| HRC60-TT4-5*50 | 5 | 6 | 13 | 50 | 4 |

| HRC60-TT4-6*50 | 6 | 6 | 15 | 50 | 4 |

| HRC60-TT4-8*60 | 8 | 8 | 20 | 60 | 4 |

| HRC60-TT4-10*75 | 10 | 10 | 25 | 75 | 4 |

| HRC60-TT4-12*75 | 12 | 12 | 30 | 75 | 4 |

| HRC60-TT4-14*100 | 14 | 14 | 45 | 100 | 4 |

| HRC60-TT4-16*100 | 16 | 16 | 45 | 100 | 4 |

| HRC60-TT4-18*100 | 18 | 18 | 45 | 100 | 4 |

| HRC60-TT4-20*100 | 20 | 20 | 45 | 100 | 4 |

| HRC60-TT4-4*75 | 4 | 4 | 16 | 75 | 4 |

| HRC60-TT4-4*100 | 4 | 4 | 20 | 100 | 4 |

| HRC60-TT4-6*75 | 6 | 6 | 18 | 75 | 4 |

| HRC60-TT4-6*100 | 6 | 6 | 30 | 100 | 4 |

| HRC60-TT4-6*150 | 6 | 6 | 45 | 150 | 4 |

| HRC60-TT4-8*75 | 8 | 8 | 25 | 75 | 4 |

| HRC60-TT4-8*100 | 8 | 8 | 35 | 100 | 4 |

| HRC60-TT4-8*150 | 8 | 8 | 50 | 150 | 4 |

| HRC60-TT4-10*100 | 10 | 10 | 40 | 100 | 4 |

| HRC60-TT4-10*150 | 10 | 10 | 55 | 150 | 4 |

| HRC60-TT4-12*100 | 12 | 12 | 45 | 100 | 4 |

| HRC60-TT4-12*150 | 12 | 12 | 55 | 150 | 4 |

| HRC60-TT4-14*150 | 14 | 14 | 60 | 150 | 4 |

| HRC60-TT4-16*150 | 16 | 16 | 70 | 150 | 4 |

| HRC60-TT4-20*150 | 20 | 20 | 70 | 150 | 4 |

■ Our Carbide Square End Mills are meticulously crafted to provide superior accuracy and surface finish when working with Titanium Alloy, enabling you to achieve tight tolerances and intricate details.

■ Engineered with high-quality carbide materials, these end mills exhibit exceptional toughness and wear resistance, ensuring prolonged tool life and minimizing downtime for tool changes.

■ The end mills feature an optimized cutting-edge geometry designed to reduce chatter and vibrations during machining, resulting in smoother cuts and improved overall performance.

■ Titanium Alloy machining generates high temperatures. Our end mills are equipped to handle these extreme conditions, maintaining their cutting edge integrity and performance even under elevated temperatures.

■ The flute design of our Carbide Square End Mills enhances chip evacuation, preventing chip build-up and ensuring efficient material removal, leading to improved productivity.

■ Experience faster material removal rates and reduced cycle times, thanks to the efficiency and precision of our Carbide Square End Mills.

■ The exceptional wear resistance and toughness of our end mills contribute to prolonged tool life, reducing the frequency of tool replacements.

■ Achieve reliable and consistent results with each machining operation, ensuring quality and repeatability in your projects.

■ By increasing machining efficiency and tool longevity, our Carbide Square End Mills offer potential cost savings by optimizing your machining processes.

Aerospace Components

Medical Implants

Automotive Parts

Industrial Components

When it comes to machining Titanium Alloy, precision and performance are paramount. Our Carbide Square End Mills for Titanium Alloy combine cutting-edge design with superior materials to provide a reliable solution for your machining needs. Experience the power of precision, durability, and efficiency with our end mills – the key to unlocking exceptional results in Titanium Alloy machining.