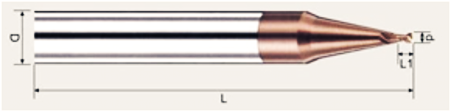

Micro carbide end mills for small diameter holes

HRC: 60

Grain Size: 0.2UM

Flutes: 2

Coating: AlTiN

Application: Tool steel, quenched and tempered steel, Carbon steel, cast iron; Professionfor Copper & Aluminum

Non-standard production & OEM is welcomed anytime.

When it comes to machining intricate and precise details, Carbide Micro Square End Mills stand out as indispensable tools. These end mills, crafted from high-quality carbide material, are specifically designed to excel in applications that require fine surface finishes and tight tolerances.

Carbide Micro Square End Mills

| Type | d | D | L1 | L | Flute |

| HRC60-MS2-0.1*50 | 0.1 | 4 | 0.2 | 50 | 2 |

| HRC60-MS2-0.15*50 | 0.2 | 4 | 0.3 | 50 | 2 |

| HRC60-MS2-0.2*50 | 0.2 | 4 | 0.4 | 50 | 2 |

| HRC60-MS2-0.3*50 | 0.3 | 4 | 0.6 | 50 | 2 |

| HRC60-MS2-0.4*50 | 0.4 | 4 | 0.8 | 50 | 2 |

| HRC60-MS2-0.5*50 | 0.5 | 4 | 1.0 | 50 | 2 |

| HRC60-MS2-0.6*50 | 0.6 | 4 | 1.2 | 50 | 2 |

| HRC60-MS2-0.7*50 | 0.7 | 4 | 1.4 | 50 | 2 |

| HRC60-MS2-0.8*50 | 0.8 | 4 | 1.6 | 50 | 2 |

| HRC60-MS2-0.9*50 | 0.9 | 4 | 1.8 | 50 | 2 |

The Micro Square End Mills are cutting tools that are used to mill and shape materials in various industries, such as aerospace, automotive, medical, and electronics. They are typically made from solid carbide material, which provides high strength, durability, and wear resistance for long-lasting performance.

Micro square end mills feature a square-shaped cutting edge with sharp corners, which allows for precise machining of small parts and intricate details. They come in a range of sizes and geometries to accommodate different machining applications, including roughing, finishing, and profiling.

These end mills are commonly used in CNC milling machines, which are computer-controlled cutting systems that can produce complex shapes and patterns with high accuracy and repeatability. By using aluminum cutting end mills, manufacturers can achieve tight tolerances and excellent surface finishes on their parts, which is critical for meeting quality standards and reducing production costs.

End mills possess several features that make them ideal for demanding machining tasks. Let's delve into their key characteristics:

Micro Size: As the name suggests, these end mills have micro-sized cutting edges and overall dimensions. The small size allows for intricate and precise machining, enabling the creation of fine details and tight corners.

Carbide Material: Carbide is a popular choice for Micro Square End Mills due to its exceptional hardness, wear resistance, and ability to withstand high temperatures. Carbide end mills maintain their sharp cutting edges for longer periods, resulting in extended tool life and improved machining efficiency.

Square End Design: Carbide Micro Square End Mills feature a square cutting edge, allowing for efficient cutting and profiling of flat surfaces. The square end design creates sharp corners and clean edges, contributing to the overall precision of the machined components.

Flute Design: These end mills typically have multiple flutes, which are the spiral grooves along the cutting edge. The flute design helps with chip evacuation, preventing chip buildup and ensuring smooth cutting action.

Coating Options: Carbide Micro Square End Mills often come with various coating options, such as TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride). These coatings provide increased hardness, lubricity, and heat resistance, further enhancing the tool's performance and prolonging its lifespan.

The utilization of Carbide Micro Square End Mills brings several advantages to precision machining processes:

High Precision: With their micro-sized cutting edges, these end mills excel in achieving intricate and detailed machining results. They enable precise contouring, profiling, and slotting of small workpieces, contributing to the overall quality of the finished components.

Excellent Surface Finish: Carbide Micro Square End Mills deliver exceptional surface finishes, characterized by smoothness and minimal tool marks. This aspect is crucial in applications where aesthetics and fine details are paramount, such as jewelry making or electronics manufacturing.

Versatility: Despite their small size, Carbide Micro Square End Mills exhibit versatility in their applications. They can be used for machining various materials, including plastics, soft metals, and even certain types of hardened steels, making them suitable for a wide range of industries.

Extended Tool Life: Thanks to the durability and wear resistance of carbide material, these end mills offer prolonged tool life compared to traditional high-speed steel end mills. This reduces tool change frequency, saving time and costs in production.

Increased Efficiency: Carbide Micro Square End Mills enable high-speed machining with improved chip evacuation, reducing cycle times and increasing overall machining efficiency. Their ability to maintain sharp cutting edges for extended periods further enhances productivity.

Carbide Micro Square End Mills find extensive use in various precision machining applications, including:

◇Jewelry making

◇Microelectronics

◇Microfluidics

◇Aerospace components

◇Medical devices

◇Prototyping

◇Engraving

◇Fine woodworking

Their ability to handle intricate details and deliver superior surface finishes makes them indispensable in industries that require high precision and fine craftsmanship.

Ruihan Carbide Micro Square End Mills are vital tools for achieving precision and detail in machining operations. With their micro-sized cutting edges, durable carbide construction, and excellent surface finish capabilities, these end mills elevate the quality and accuracy of machined components. Whether you're working on delicate jewelry pieces or intricate electronic parts, Carbide Micro Square End Mills provide the necessary precision and performance to achieve exceptional results.