We are delighted to introduce our latest product, the Type F Toolholder. Designed to meet the demands of precision machining, this tool holder offers exceptional quality, versatility, and reliability. It is an essential component for secure and efficient tool mounting in various machining applications.

Experience the ultimate precision and stability in machining with the Type F Toolholder. Compatible with a variety of cutting tools, this versatile tool holder ensures accurate results and secure tool insertion. Elevate your machining capabilities today!

The Type F Toolholder offers outstanding quality, versatility, and reliability for precision machining operations. With its robust construction, easy tool installation, and accurate alignment features, it enhances productivity, machining performance, and tool life. Choose our Type F Toolholder to optimize your machining processes and achieve superior results.

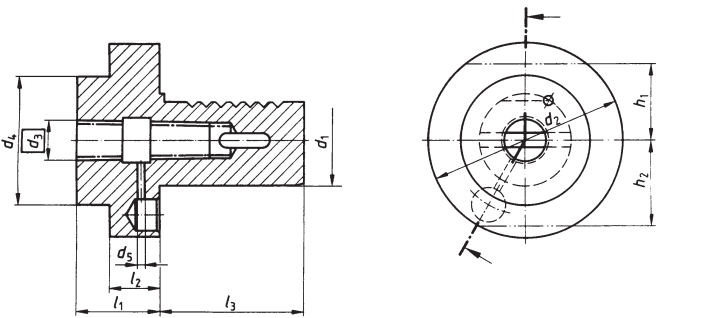

Type F Toolholder

Robust Construction: The Type F Toolholder is constructed using high-grade materials, ensuring excellent durability and reliability. It is designed to withstand the rigors of heavy-duty machining operations, providing long-lasting performance and stability.

Easy Tool Installation: The tool holder features a user-friendly design that simplifies tool installation. With its efficient clamping mechanism and intuitive interface, operators can quickly and securely mount cutting tools, minimizing setup time and enhancing productivity.

Accurate Tool Alignment: The Type F Toolholder incorporates precise alignment features, guaranteeing accurate positioning of the cutting tool. This ensures consistent and reliable machining results, reducing the need for rework and enhancing overall machining efficiency.

Versatile Compatibility: Our Type F Toolholder is compatible with a wide range of machine tool systems, making it a versatile choice for various machining centers. It supports different tool sizes and configurations, accommodating diverse machining requirements and offering flexibility to operators.

Rigidity and Stability: The tool holder design prioritizes rigidity and stability, minimizing vibration and deflection during machining operations. This results in improved surface finishes, extended tool life, and enhanced dimensional accuracy in the machined components.

Enhanced Productivity: The Type F Toolholder streamlines the tool mounting process, reducing setup time and increasing machine uptime. It enables efficient tool changes, allowing operators to maximize productivity and meet demanding production schedules.

Superior Machining Performance: The precise tool alignment and robust construction of the tool holder contribute to improved machining performance. With reduced vibration and enhanced stability, operators can achieve higher cutting speeds, improved surface finishes, and tighter tolerances.

Increased Tool Life: The Type F Toolholder's rigid and stable design helps minimize tool wear and prolong tool life. By reducing deflection and optimizing cutting conditions, it minimizes the risk of tool breakage and ensures consistent performance, ultimately reducing tooling costs.

Versatile Application: Our Type F Toolholder supports a wide range of machining applications, including milling, drilling, and reaming. Its compatibility with various cutting tools and machine tool systems makes it suitable for industries such as automotive, aerospace, mold making, and general machining. Click For More.

The Type F Toolholder is designed to excel in the following applications:

●Milling operations: Face milling, peripheral milling, and slotting

●Drilling operations: Hole drilling, counterboring, and chamfering

●Reaming operations: Precision hole sizing and surface finishing

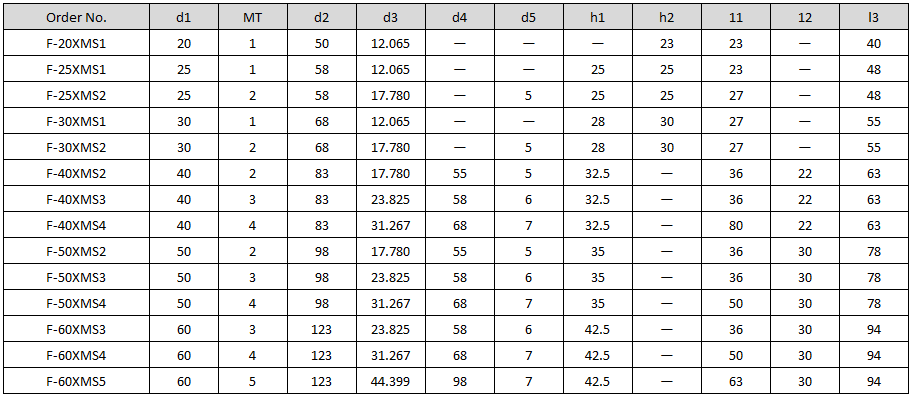

Our Type F Toolholder is available in different sizes and configurations to accommodate specific customer requirements. For detailed product information and availability, please refer to our catalog or contact our sales team.

Q: What is the Type F Toolholder?

A: The Type F Toolholder is an advanced tool holder designed for precision machining. It offers exceptional stability, versatility, and ease of use, making it an ideal choice for professionals and enthusiasts.

Q: What are the key features of the Type F Toolholder?

A: The Type F Toolholder is known for its unparalleled precision and stability. It has a rigid construction to minimize vibrations and ensure consistent results. It is also highly versatile, compatible with various cutting tools, and features a secure tool insertion mechanism.

Q: What applications is the Type F Toolholder suitable for?

A: The Type F Toolholder is suitable for a wide range of applications, including milling, drilling, and turning. It accommodates different cutting tools such as drills, end mills, and reamers, providing flexibility and convenience in machining operations.

Q: How does the Type F Toolholder enhance machining accuracy?

A: The Type F Toolholder's rigid construction minimizes vibrations, resulting in improved machining accuracy. It provides a stable platform for the cutting tool, allowing for tight tolerances, reduced rework, and enhanced overall machining quality.

Q: Is the tool insertion process easy and secure?

A: Yes, the Type F Toolholder features a user-friendly design for quick and secure tool insertion. It utilizes a spring-loaded mechanism that ensures a tight grip on the cutting tool, preventing slippage and enhancing operator safety.

Q: Can the Type F Toolholder be used in high-volume machining operations?

A: Absolutely! The Type F Toolholder's efficient tool change process and secure tool insertion make it an excellent choice for high-volume machining operations. It minimizes downtime and boosts productivity, ensuring seamless workflow.

Q: Are there any specific maintenance requirements for the Type F Toolholder?

A: The Type F Toolholder requires minimal maintenance. Regular cleaning and inspection for any signs of wear or damage are recommended. Lubricating the tool holder periodically will help maintain its performance and extend its lifespan.

Q: Is the Type F Toolholder compatible with different machine types?

A: Yes, the Type F Toolholder is designed to be compatible with a wide range of machine types commonly used in precision machining. It can be used with various CNC machines, milling machines, and lathes, among others.

Q: Where can I purchase the Type F Toolholder?

A: The Type F Toolholder is available for purchase from RUIHAN, a reputable tooling supplier and online marketplace specializing in machining tools and accessories. You can contact us to meet your specific requirements.

Q: Does the Type F Toolholder come with a warranty?

A: It is recommended to check the warranty details with us or consult the product documentation to understand the specific warranty coverage for the Type F Toolholder you intend to purchase.