5C collets are designed for work holding. 5C collets have an external thread at the rear for drawing the collet closed, allowing workpieces to pass right through the center of the collet and chuck (5C collets often also have an internal thread for locating a workpiece against the inserted work stop).

5C collets tightly grip workpieces when installed into a 5C collet chuck or holder. They provide a stronger hold on small workpieces than a standard lathe chuck.

C collets are available in the inch size and metric size .

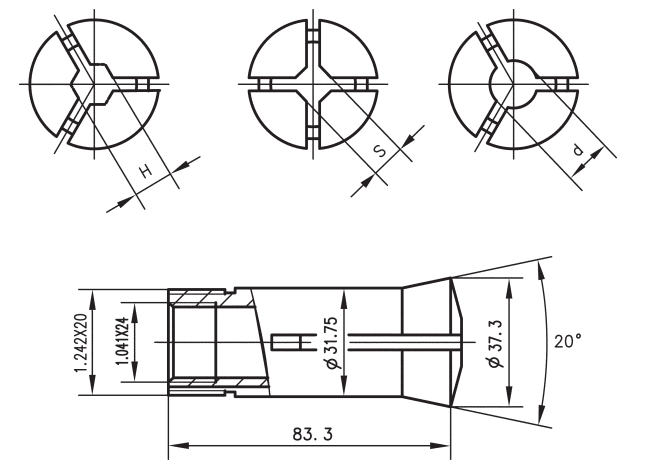

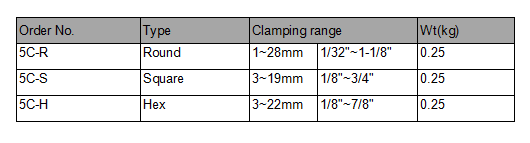

Collets in round size are 1mm-28mm, square and hex collets size are 3-19mmm.

Precision grade (runout ≤0.015mm)

Hardened and ground ( The clamping part hardness HRC55-60, The elastic part HRC40-45)

High grade steel for long wear life (Steel material :65Mn)

Inch or Metric Size

Available With adjustable collet /workpiece stop

Can be used 5C collet fixture

Kits are available .

What is the difference between 3C and 5C collets?

The difference between 5C and 3C is basically size. The 3C has an upper limit of 1/2" (I have seen a few 9/16" ones) and 5C has the upper limit of 1-1/8". The 5C is much more widely used and therefore easier and cheaper to acquire.

What is the difference between 5C and ER collets?

the difference between ER & 5C collets is that ER collets are slotted from both ends and therefore will close at the back as well as the front. this gives them a greater gripping range of diameters than a 5C collet which are split from the front only, typically a range of 1mm

In general, 5C collets are the famous standard for lathe and millwork. It is used to hold the cylindrical stock of around 1″ (25 mm) diameter. 5c collet can provide exceptional concentricity to speed up setup than three jaw chucks without any issues.